Introduction

A Variable Frequency Drive (VFD) is a type of electrical device used to control the speed and torque of AC motors in a wire drawing machine. By controlling the frequency of the AC voltage supplied to the motor, the VFD can adjust the motor speed and regulate the tension in the wire, ensuring consistent and efficient wire drawing. This results in improved production speed and reduced energy consumption, as well as greater control over the wire drawing process.

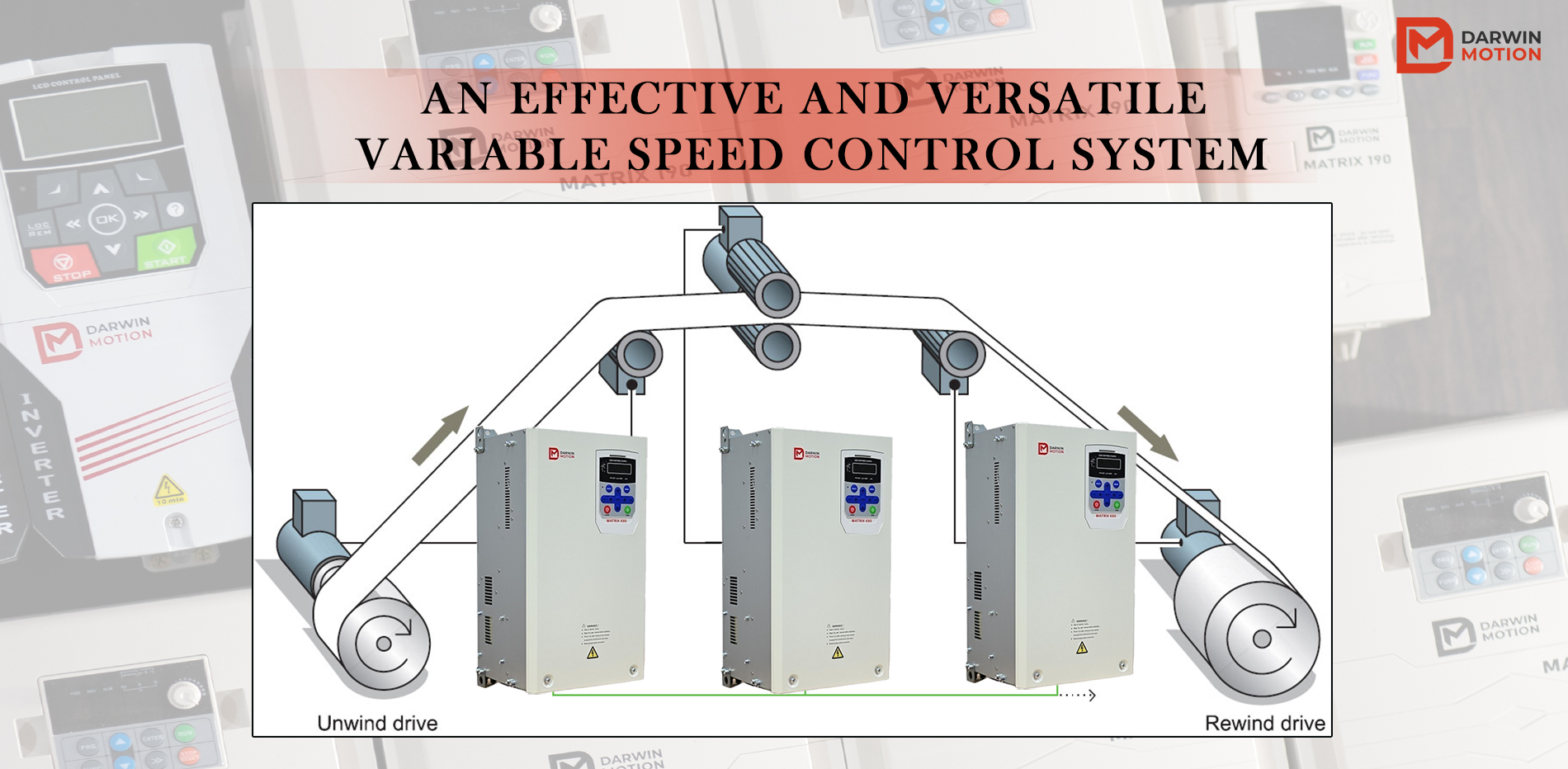

Variable frequency drive often called Variable Frequency Drive, or variable speed drive, frequency inverter is a common device to control AC motor in variable speed operating to save electricity bills.

The variable frequency drive basic system includes an AC motor, operator interface, and controller. However, recently, since electrical applications have turned out more complexes and obscure, not like a variable speed drive, a variable frequency drive have the capability to optimally manage the motor's direction and speed that leads to high-performance results.

THINGS TO CHECK BEFORE CHOOSING VARIABLE FREQUENCY DRIVES

- Since Variable Frequency Drives have limited over-current capacity, so difficult-to-start loads might require an over-sized device to match higher current demands.

- For knowing how many motors, the drive must control have to be estimated the total peak currents of entire motor loads under the poorest functioning conditions your planned system will observe. Size your VFD base on the maximum current need.

- Overheating of motor could be a possible concern for any of your intended drive applications such as low speed, constant torque.

- Since smaller motors are not considered much efficient than larger ones, so improvements because of the variable frequency drive will possibly be willingly apparent. However, as large motors ingest higher power, so small enhancement in efficiency can lead to considerable savings over the motor’s life.

- In volatile condition, ensure all used materials are strong to chemical attack and are correctly grounded; while for an atmosphere alive with particulates, make sure correct sealing; and for high temperatures, permit cooling.

- Always choose a drive that trips quickly in an over-current condition or the one that keeps up stable engine force and lower engine speed to continue current needed.

- Also it is essential to understand load downtimes and have the choice to do a thorough fault analysis.

- Likewise, the utilization of VFDs has massively improved product quality and significantly reduced production costs. Because of its low downtime, many businesses are using VFDs. VFD offers best protection against many issues such as overvoltage, under voltage, phase protection, and electro thermal overloads. Also, industries are using Variable Frequency Drives as they offer efficient speed for applications, no mistakes, and higher production yields. Several business using utilize VFDs have even integrated Ethernet in the industrial applications they use. It completely simplifies the operations. According to Darwin Motion – VFD & Servo Drive Manufacturer survey, 75% of machine operator say they have been using or considering Ethernet in industrial applications. This current trend is being seen in VFD introductions too.

Working Principle

The VFD drives are often provided with the three-phase voltage supply for powering the motor. The Variable Frequency Drive includes three main components such as VFD controller, inverter and feedback device.

- Three-level VFD controller: The VFD controller works on the basis of desired rpm value, which is offered by the computer. The computer first received the VFD controller and then the feedback device of VFD controller detects it. The Variable Frequency Drive then operate on this information for controlling the motor’s speed.

The Variable frequency controller is liable to converts low voltage dc input into consistent output for v/f conversion, increases ac power magnitude according to output and last feeds to v/f converter.

- Configuration of VFD inverter: The VFD inverters are utilized for converting input power into three phase output ac. This VFD inverter include six IGBTs in the case of six-pulse v/f configuration and 12 pulse v/f configuration Variable frequency drive inverter.

- The VFD inverter includes three main parts namely input, output and control terminals. There are 3 power equipment in VFD inverter such as IGBTs, thyristors and SCRs and often IGBTs and thyristors are linked in the case Variable Frequency Drive inverter as per 3-phase v/f configuration.

- The VFD inverters are made for converting low voltage dc input into relative ac output with v/f conversion and increasing the ac power magnitude according to v/f setting. If we wish to increase the motor’s speed, then we must increase the v/f ratio.